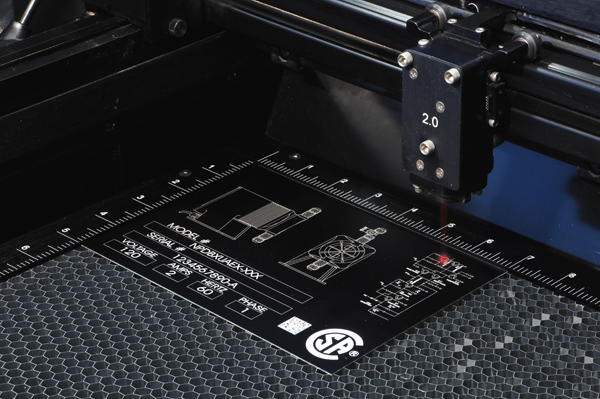

Laser marking is the process of marking an object using a laser. This process does not require any contact to be made with the item that is being marked. This is advantageous over other types of marking processes because in a contact-marking process, there is an additional medium applied to the surface of the material that could scratch off or fade with time. There is no need for retooling when using laser marking. Laser marking is permanent yet it does not remove any material or cause deformation.

Laser Metal Marking

Using Universal’s High Power Density Focusing Optics (HPDFO)™ Universal systems can even mark some metals. The laser’s power density is increased by using this special accessory. The HPDFO makes it possible to directly mark stainless steel, iron, titanium, chromed steel and some exotic high-carbon metals without the need for metal marking compounds.

Laser Marking Software

Universal Laser Systems has an advanced laser print driver for laser material processing systems. The print driver, Laser Interface+, has advantageous features for laser marking processes. Laser Interface+ is easy to learn increasing productivity. There is a print preview function ensures that your laser markings are properly setup. The software stores and can re-run up to 2,000 jobs without the need to open graphics software.