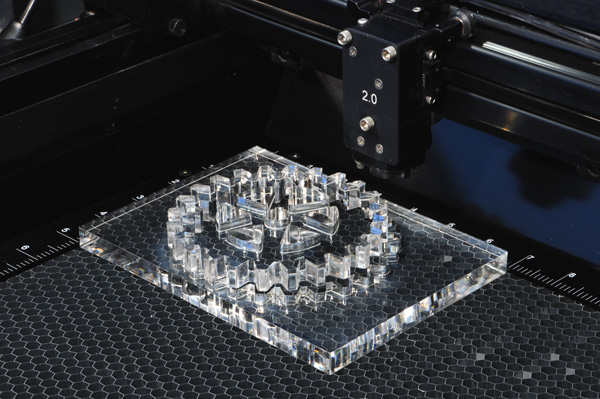

Laser Cutting is the process of cutting an object using a laser. One advantage of this process is that laser cutting does not require contact to be made with the item being cut. In contrast, in a contact-cutting process, the bit or other type of cutting tool must be replaced when it becomes worn. Laser cutting also requires no retooling or recasting of dies for multiple applications. Because laser cutters are cnc machines, merely changing software settings starts a radically different laser cutting application.

Laser Cutting Machines Chicago – Scientific Spectrum Midwest Inc.

Laser cutting machines, or laser systems, are machines that consist of a laser and have a surface to place an object to be laser cut. The laser cutting machines typically have an enclosure to protect the user from the laser being used. Most objects sit stationary while being cut. During the laser cutting process, a carriage with a lens moves on an X, Y axis to cut the object. Laser cutting machines also include a Z axis that is set prior to cutting based on a variety of variables.

Laser Cutting Software Chicago – Scientific Spectrum Midwest Inc.

Universal Laser Systems has an advanced laser print driver for laser material processing systems. The print driver, Laser Interface+, features advantages specific to laser cutting. The same laser cutting job can have different cutting power levels and speed settings which can help to increase production efficiencies. When a laser cutting job requires high-accuracy, the driver enables the user to scale the vector graphic to compensate for material melt-back and beam diameter.